How Not to Break Your Cryogenic Cuvettes

/Greetings of the day!

To crush your cuvettes, to see them driven before you and to hear the lamentations of your lab managers!

Today we're going to focus on a topic close to our hearts here at FireflySci, mainly that of NOT breaking your cryogenic cuvettes.

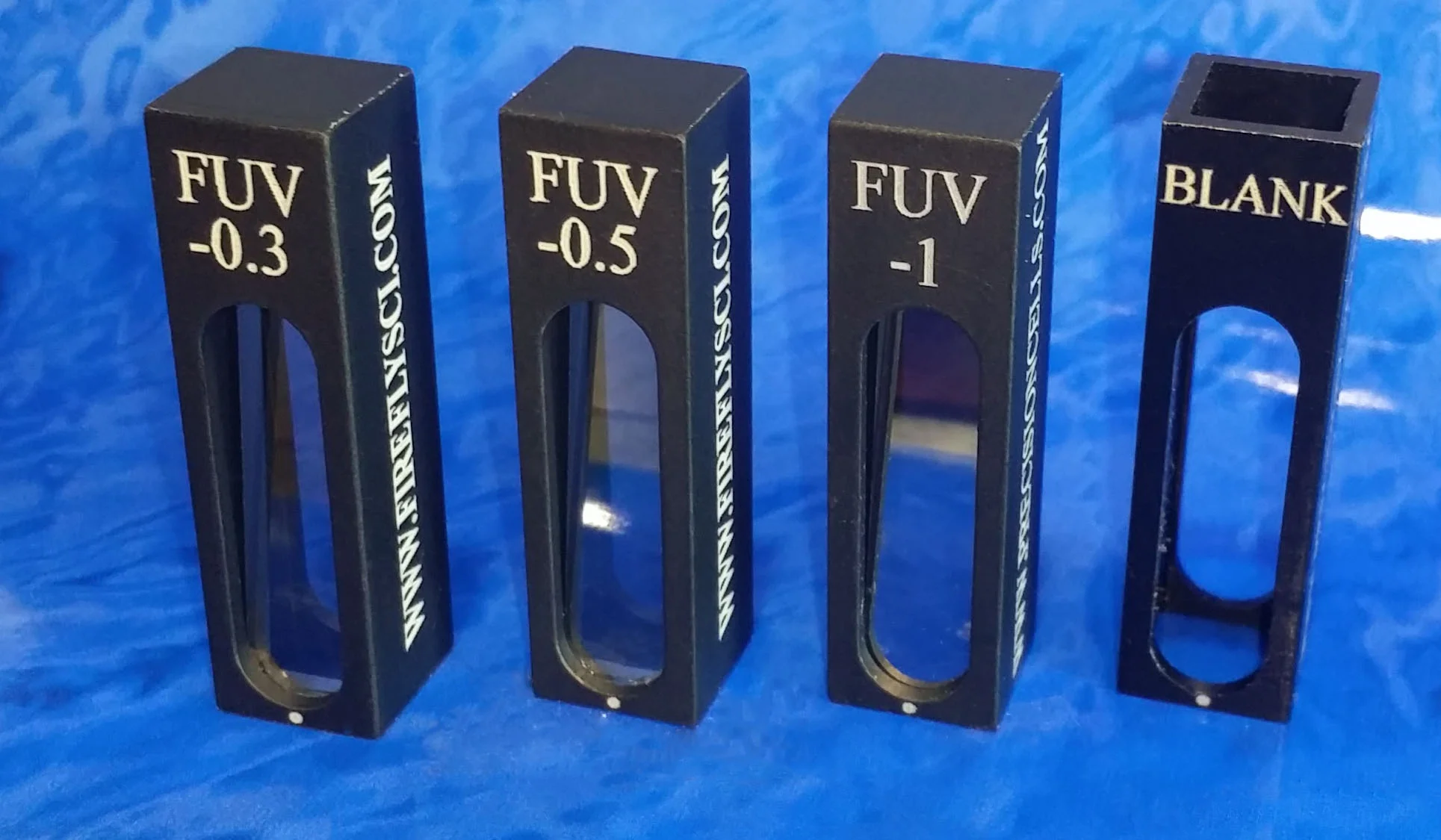

Most cuvettes are not made for cryo applications and will shatter in miraculous fashion when you expose them to temperatures in the low kelvins. A surefire way to accomplish this is to rapidly drop the temperature or bring it up and you will see something approaching the cell to the right. FireflySci, however, has a line of cryogenic cuvettes specifically made to survive these conditions better than most.

Closeup on our cryogenically fused 64fluv10 cuvette

To begin with, our cryo cuvettes are made from our UV Quartz (Suprasil 3001) material, which can endure thermal shock better than most. We also perform custom fusing with specific emphasis on making sure our edges and corners are protected as they are the most common areas where cracking starts.

The cause of thermal shock is when an abrupt change in temperature causes the cuvette to expand or contract at differing rates in different areas. This will cause a strain that can manifest as a small hairline crack and eventually a full-on shatter. A good way to visualize this is what happens when you place an ice cube into a warm glass of water. There is a distinct noise as the cracks appear immediately all over the cube.

The way to avoid this is not particularly complicated but it is important. Here are a couple of tips to avoid issues:

1. Slow (I mean SLOOOWWWW) cool-down and heat-up.

Don't be like T1000. Cool and warm up those cuvettes very, very slowly!

This is the one single way to avoid cracks with our cryogenic cuvettes. If you are going to be dropping your Cryostat down to 77K there is no way to overemphasize the importance of slowly bringing the temperature down and then bringing it back up. AT LEAST an hour for cool-down and AT LEAST an hour for warm-up should be used.

If you think you haven't given it enough time to cool off and heat up disregard this feeling and let it cool even longer!

2. Don't add a sample of a different temperature into the cuvette.

If you have a very cold cryo cuvette that has not fully warmed up it would be ill-advised to drop a room temperature sample into the chamber. Think of the ice cube example from above.

3. Add fluid directly down the center of the cuvette via funnel or nozzle.

One surefire way to create a temperature gradient that can shatter a cuvette is to pour a warmer sample down the side of a wall. What this would do is create a large difference in temperature on the walls increasing your risk of breakage. It is often a better idea to insert your sample beforehand to avoid this issue.

4. Avoid handling right away

If you have just taken the cuvette out of your Cryostat make sure not to handle it right away. The reason for this is that your cuvette might still be very cold and the heat from your hand might cause an abrupt fluctuation in temperature leading to fissures and shattering. Try to wait at least 30-45 minutes before handling the cuvette.

Here's to your shatter-less success!

The FireflySci Team

![firefly_logo_FINAL [Black].jpg](https://images.squarespace-cdn.com/content/v1/5411d5c0e4b02e1c8b27565a/1434491508803-XB4OF7YDY46Z72L5U5AP/firefly_logo_FINAL+%5BBlack%5D.jpg)