Microfluidic Devices: Advancing Precision in Fluid Dynamics

/Microfluidic devices manipulate incredibly small volumes of fluids within micro-scale channels, enabling a level of precision and efficiency that is reshaping scientific research, diagnostics, and industrial applications. Often referred to as lab-on-a-chip systems, these platforms condense complex laboratory procedures into compact, automated devices, providing faster results, greater reproducibility, and reduced operational costs.

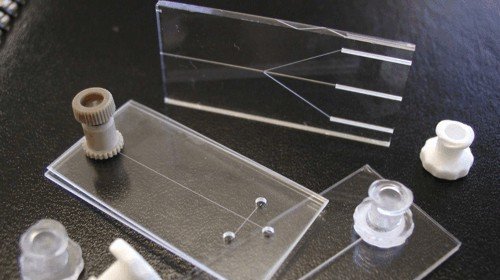

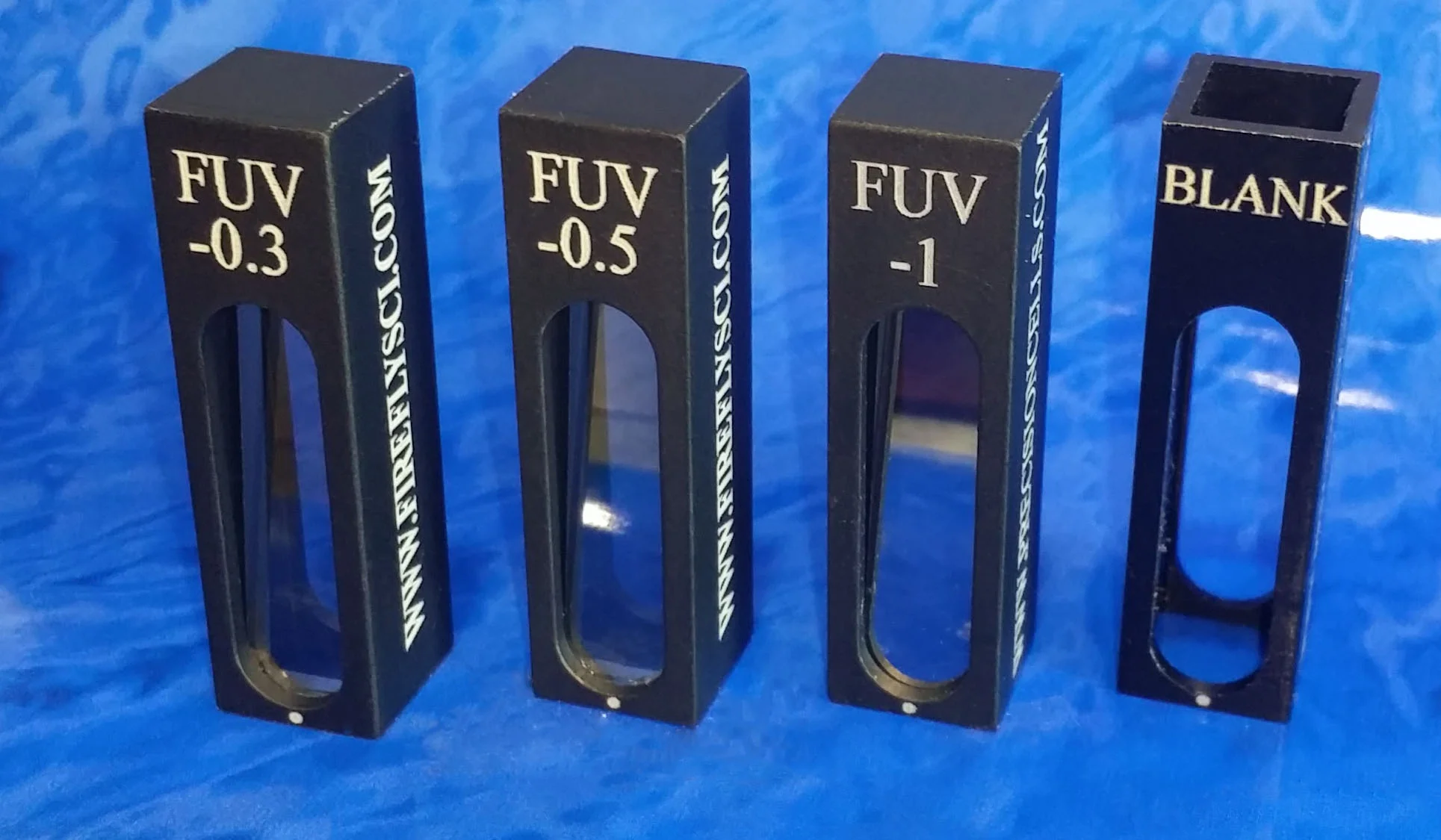

At the forefront of this field are microfluidic chips from FireflySci, meticulously engineered for consistent performance, scalability, and user-friendly integration into diverse experimental setups.

A Brief History: From Early Concepts to Modern Microfabrication

The development of microfluidics can be traced back to innovations in microelectronics and inkjet printing in the 1950s, which demonstrated the feasibility of manipulating fluids at extremely small scales. The late 1970s saw the creation of the first silicon-based miniaturized gas chromatographs, sparking interest in compact fluid control systems. By the 1980s, Micro-Electro-Mechanical Systems (MEMS) emerged, bridging electronics and microfluidics and setting the stage for high-precision fluid handling.

A pivotal moment came in the late 1990s with the advent of soft lithography using PDMS, pioneered at Harvard, which dramatically lowered the barriers to microfluidic device fabrication. This technology allowed for rapid prototyping and opened the field to a broader range of applications and researchers.

Why Microfluidics Matter

Microfluidic devices offer advantages that traditional laboratory systems cannot match:

Minimal Sample Requirements: Operations can be performed using nanoliter or even picoliter volumes, significantly reducing reagent use and costs.

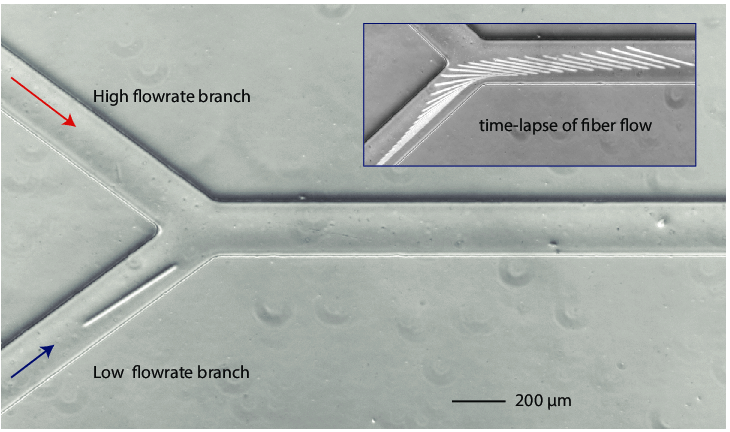

Rapid Processing: Short diffusion distances accelerate chemical reactions and biological assays.

Enhanced Precision: Micro-scale control over fluid flow, temperature, and chemical gradients ensures reproducibility.

Automation and Integration: On-chip control systems minimize human error and streamline complex workflows.

Portability: Compact designs enable field diagnostics, environmental testing, and remote analysis.

Key Applications Across Fields

Microfluidic devices are making a profound impact across multiple sectors. In point-of-care diagnostics, they enable rapid detection of infectious diseases in both urban hospitals and remote locations, reducing diagnostic time from days to minutes. For single-cell genomics, microfluidics allow scientists to study individual cells in isolation, revolutionizing cancer research, immunology, and regenerative medicine.

In drug discovery and development, high-throughput screening on microfluidic platforms allows simultaneous testing of thousands of compounds, expediting pharmaceutical pipelines. Environmental monitoring benefits from real-time detection of pollutants, heavy metals, and pathogens in water sources, enhancing public health protection. The food industry relies on these devices for rapid identification of contaminants, improving safety and compliance.

Advanced chemical synthesis in micro-reactors enables precise control of reaction parameters, fostering innovation in material science. Biomedical research is leveraging organ-on-a-chip technology to model human organs for drug testing and disease modeling, reducing reliance on animal testing. In the emerging field of space bioscience, microfluidics provide a means to study biological processes in microgravity, aiding long-duration space exploration.

Choosing the Right Platform

Material selection influences performance and suitability for different applications:

PDMS: Transparent, flexible, ideal for prototyping and biological studies.

Glass or Silicon: High durability and chemical resistance for industrial or analytical chemistry applications.

Plastics: Affordable, disposable options suitable for large-scale diagnostic deployment.

FireflySci: Precision-Engineered Microfluidic Chips

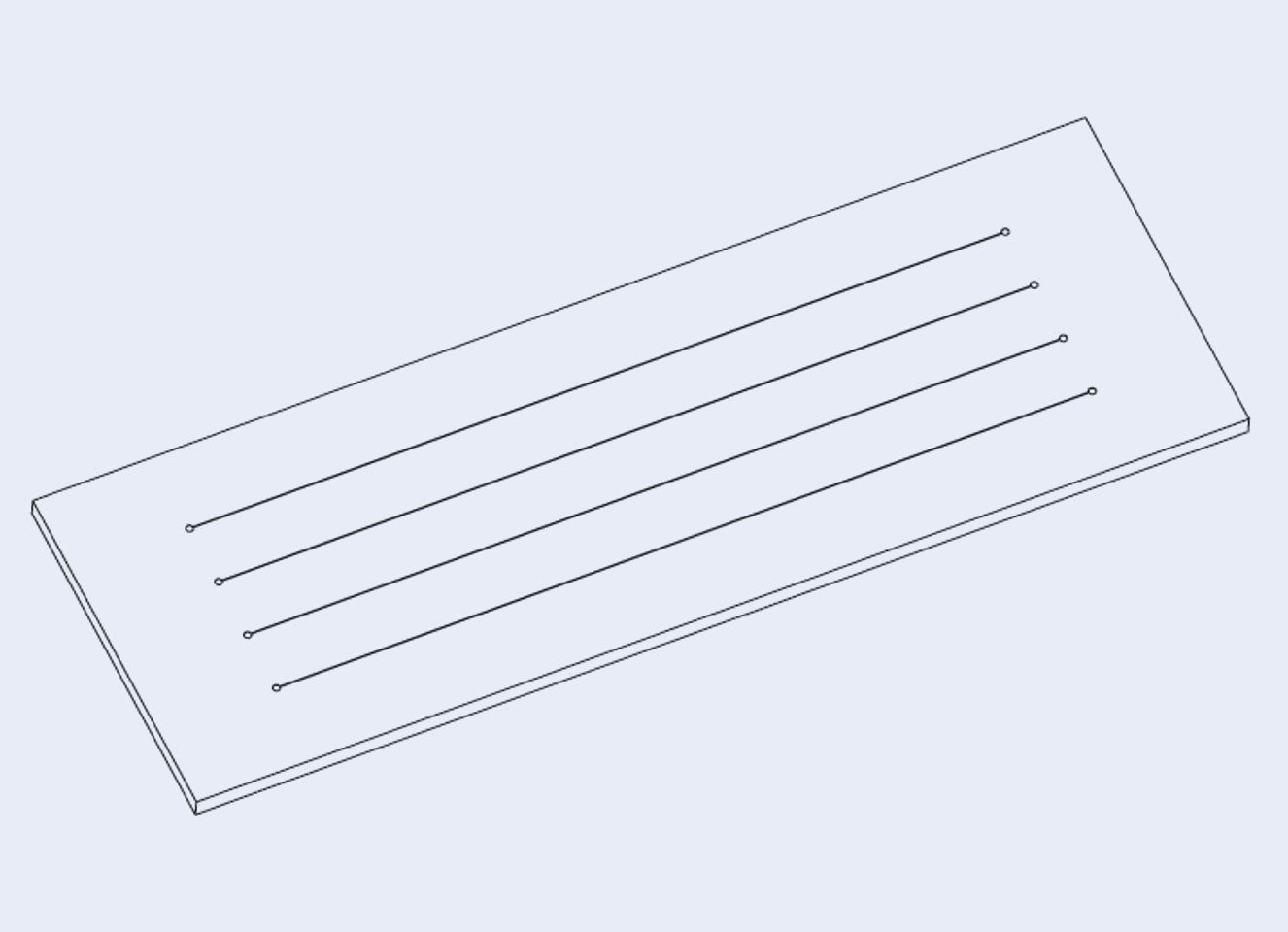

FireflySci’s microfluidic chips blend advanced microfabrication techniques with practical usability. Designed to meet the rigorous demands of academic, clinical, and industrial users, these chips maintain consistent performance in even the most challenging conditions.

With compact, accurate, and reliable microfluidic devices, FireflySci empowers groundbreaking research, faster diagnostics, and innovative industrial solutions—pushing the boundaries of what’s possible in fluid dynamics.

![firefly_logo_FINAL [Black].jpg](https://images.squarespace-cdn.com/content/v1/5411d5c0e4b02e1c8b27565a/1434491508803-XB4OF7YDY46Z72L5U5AP/firefly_logo_FINAL+%5BBlack%5D.jpg)