How to Choose Your Lab-on-a-Chip

/Microfluidic chips, also known as lab-on-a-chip, have revolutionized many fields, including analytical chemistry, biomedical research, and medical diagnostics. These chips are designed to manipulate fluids at the microscale level with channels and chambers that are often less than a millimeter in size. They are essentially tiny laboratories that can be used to perform a wide range of experiments and tests on small quantities of fluids.

However, there are many types of chips that are all fit for very specific purposes. Knowing which chip you need is crucial and the task can be daunting. This article will help you learn the differences between the types of microfluidic chips we offer at FireflySci and which type is best suited for you.

let us chip away at your apprehension

Different Types of Chips Connectors

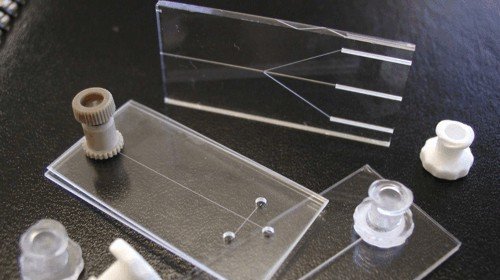

The luer lock connector in all its majesty

There are two prevalent connectors of note when concerning microfluidic chips- the Luer Lock and the Upchurch.

Luer connectors are widely used in the medical field and are designed to connect tubing to syringes or needles. The connector is a tapered cone-shaped fitting with a luer lock mechanism that ensures a tight and secure connection.

The Luer connector is designed for easy connection and disconnection, making it ideal for applications that require frequent changes in the fluid path. The Luer connector is made from polypropylene or polycarbonate materials, which are biocompatible and can withstand a wide range of chemicals and solvents.

On the other hand, Upchurch connectors are commonly used in analytical chemistry applications and are designed for high-pressure applications.

The Upchurch connector has a threaded design that allows for a more secure connection than the Luer connector. The connector is made from high-performance materials such as PEEK or stainless steel that can withstand high pressures and temperatures. The threaded design of the Upchurch connector ensures a leak-proof seal, making it ideal for applications that require precise control over the fluid path.

What'‘s up church? THis is Upchurch.

The main difference between the two connectors is their suitability for different applications. The Luer connector is ideal for applications that require frequent changes in the fluid path, while the Upchurch connector is more suitable for high-pressure applications that require a more secure and leak-proof connection.

Additionally, the materials used to make the connectors also differ. Luer connectors typically are made from polypropylene or polycarbonate and Upchurch connectors are made from high-performance materials such as PEEK or stainless steel.

One of our rare 4 channel connectors.

Channel Types

The second area to research when it comes to a microfluidic chip is the channel type you need. Differentiating the many types is key to understanding which is best for you and we will review the pros and cons of each configuration.

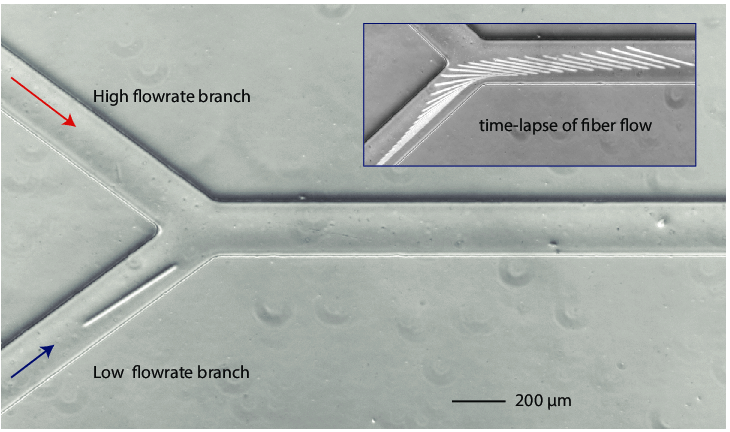

Y-Channel

Y-channels, also known as bifurcated channels, are lab-on-a-chip that split into two channels. Y-channels are commonly used for sample preparation and mixing, as well as for separating and sorting particles. The Y-channel configuration is particularly useful for applications that require the separation of two different particle sizes or types. The two channels can be designed with different widths, depths, and lengths to achieve specific separation or sorting results.

Advantages of Y-Channel:

· Enables separation of two different particle sizes or types

· Allows for precise control over flow rates and mixing ratios

· Can be easily integrated with other microfluidic components

Disadvantages of Y-Channel:

· Can be difficult to fabricate due to the requirement for precise alignment of the two channels

· May suffer from clogging or particle aggregation at the junction point

· May suffer from uneven flow distribution between the two channels

Cross Channel

Cross channels, also known as cross-junction channels, are microfluidic channels that intersect at a right angle. Cross channels are commonly used for cell sorting and trapping, as well as for fluid mixing and droplet formation. The cross channel configuration enables the control of fluid flow and particle movement in two dimensions, allowing for the creation of complex fluidic networks.

Advantages of Cross Channel:

· Allows for complex fluidic networks to be designed

· Enables precise control over fluid flow and particle movement in two dimensions

· Can be used for droplet formation and cell sorting

Disadvantages of Cross Channel:

· May suffer from clogging or particle aggregation at the intersection point

· May suffer from uneven flow distribution at the intersection point

· Can be challenging to fabricate due to the requirement for precise alignment of the channels

The cross-channel chip. don’t be cross with it.

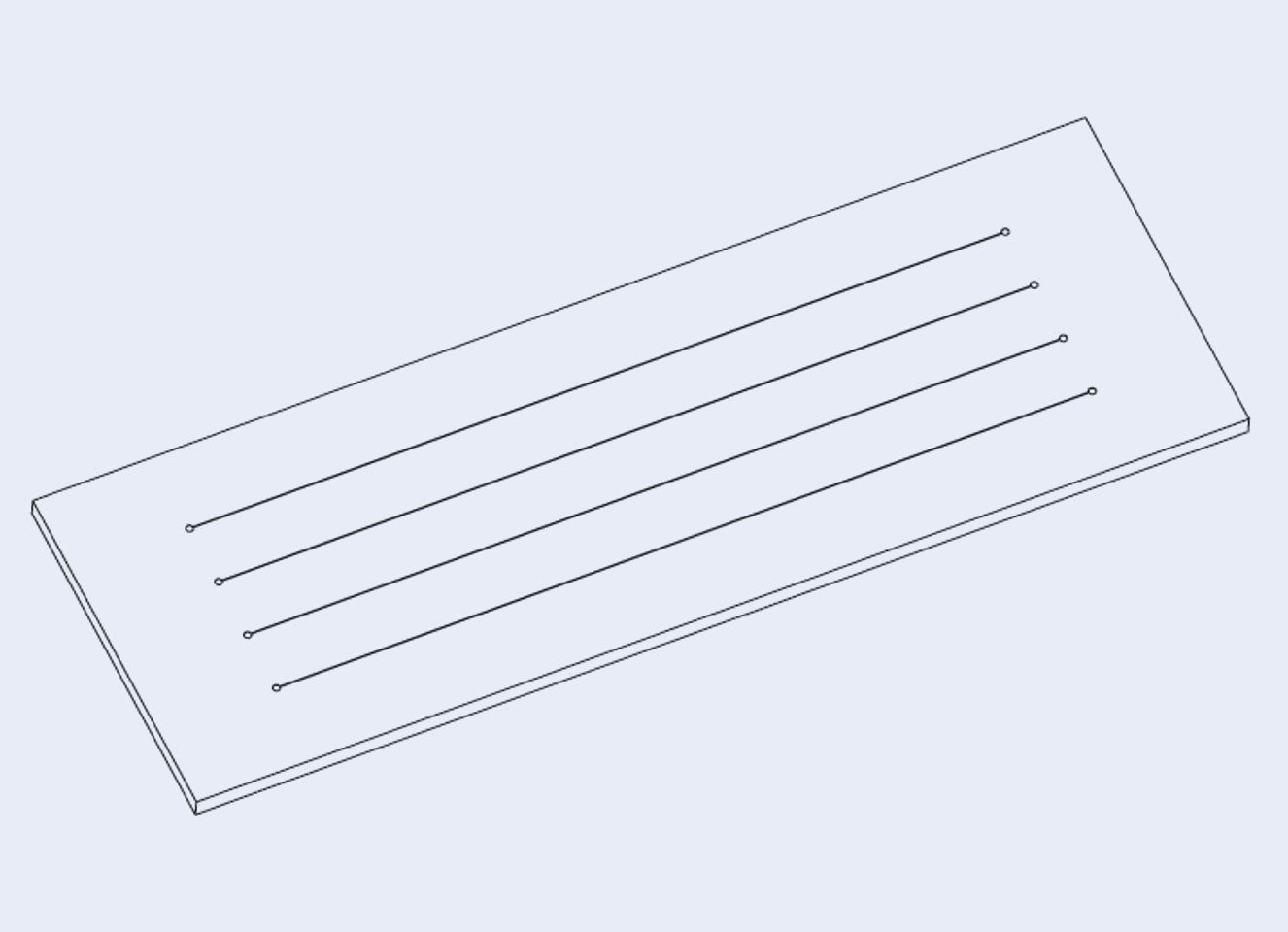

Straight Channels

Straight channels, also known as single-channel channels, are microfluidic channels that run in a straight line. Straight channels are commonly used for the transport of fluids and particles, as well as for the detection and analysis of biomolecules. Straight channels are simple in design and can be easily integrated with other microfluidic components, such as pumps and valves.

Advantages of Straight Channels:

· Offers a simple and effective way to analyze fluids and particles

· Enables easy integration with other microfluidic components

Disadvantages of Straight Channels:

· Does not offer precise control over fluid flow or particle movement

· Cannot be used for mixing or sorting applications

Straight channel lab-on-a-chip. Helping you stay on the straight and narrow

T-Channel

T-channels, also known as branched channels, are microfluidic channels that split into two channels at a T-junction. T-channels are commonly used for the manipulation of fluids and particles, as well as for the detection and analysis of biomolecules. The T-channel configuration enables the creation of complex fluidic networks and the precise control of fluid flow and particle movement.

Advantages of T-Channel:

· Enables complex fluidic networks to be designed

· Allows for precise control over fluid flow and particle movement

· Offers a simple and effective way to mix fluids

Disadvantages of T-Channel:

· Fabrication issues similar to the Y-Channel

· Clogging issues may arise

T channel chip. HE’s A chip off the ol’ block!

Lab on A Chip Materials

Microfluidic chips can be constructed from of plethora of materials and each has its own strengths and weaknesses. Inorganic materials can be essential if your solution is caustic or reactive whereas rigid polymers could be necessary if small scale prototypes are necessary.

Fused silica, also known as quartz, is a highly transparent and chemically inert material that is resistant to thermal shock. This makes it an ideal choice for microfluidic chips that require high optical clarity, such as those used in biological and chemical analysis. Fused silica also has a low coefficient of thermal expansion, which means it can withstand changes in temperature without cracking or warping.

PMMA, also known as acrylic, is a versatile plastic material that is easy to machine and mold. It is highly transparent and has a low cost, making it a popular choice for disposable microfluidic chips. PMMA is also biocompatible, making it suitable for use in biological applications.

We have the technology!

Ceramics, such as alumina and zirconia, are highly durable materials that are resistant to wear, corrosion, and high temperatures. They are often used in harsh chemical and industrial environments. Ceramics can be machined to precise tolerances, making them suitable for microfluidic chips that require high precision and stability.

Overall, the choice of material for a microfluidic chip depends on the specific requirements of the application, such as optical clarity, biocompatibility, durability, and precision. Each material has its own advantages and disadvantages, and careful consideration should be given to the selection of materials in order to ensure the best performance and functionality of the microfluidic chip.

Lab on a Chip Customization

Microfluidic chips are highly customizable with a wide range of designs and configurations available to suit different applications.

Some chips are designed for continuous flow applications, while others are designed for droplet-based assays. These chips can be integrated with other analytical techniques, such as mass spectrometry and fluorescence microscopy to provide highly sensitive and specific analyses.

Whether it’s connection type, chip design or any of the plethora of different sizes available, the best way to buy a custom chip for your lab setting is through FireflySci.

If you’d like to buy a standard microfluidic chip or customize your own unique design you can e-mail us at info@fireflysci.com or call us at +1-347-441-4277.

Here’s to your success!

-The lads and ladies at FireflySci

![firefly_logo_FINAL [Black].jpg](https://images.squarespace-cdn.com/content/v1/5411d5c0e4b02e1c8b27565a/1434491508803-XB4OF7YDY46Z72L5U5AP/firefly_logo_FINAL+%5BBlack%5D.jpg)